Hello, welcome to Guangdong Heyi Hardware Products Co.,Ltd. website!

Hello, welcome to Guangdong Heyi Hardware Products Co.,Ltd. website!

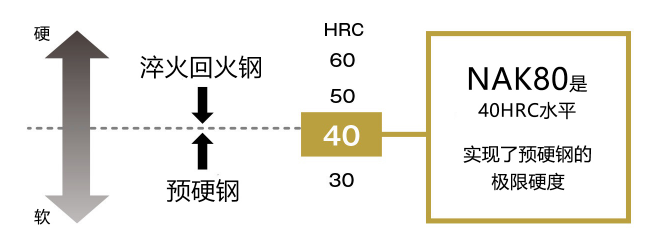

High hardness - excellent wear resistance

Both the outer and inner sides of the mould are subjected to high loads and are therefore susceptible to wear and distortion of the clamping surface and wear of the forming surface during repeated moulding operations.

With a pre-hardened hardness of 40 HRC, NAK80 has excellent wear resistance and is suitable for use in high-volume plastic forming moulds.

In addition, the age-hardened steel has a uniform hardness from the surface to the centre, making it easy to machine despite the 40 HRC level of hardness, resulting in an excellent balance between the ultimate hardness and machinability of the pre-hardened steel.

Easy to cut - cutting properties that make fine machining possible

The melted resin material reflects the shape of the moulded surface like a mirror. For this reason, plastic product moulding, where performance and aesthetics are important, requires high-precision, high-quality moulds with fine machining.

NAK80 has excellent machinability and can be used for fine moulding. The clear contours of the scored surface and the low burr on the edges make it a widely supported steel for precision plastic moulding.

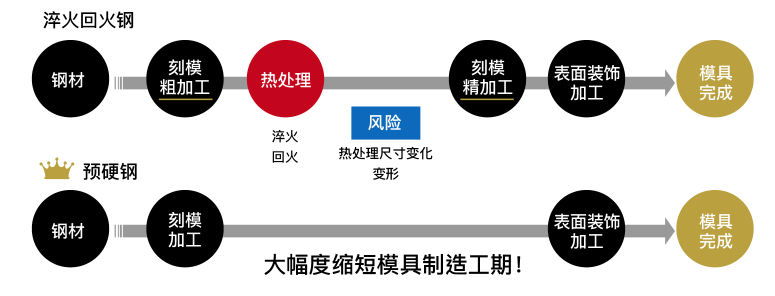

No heat treatment required - easy to use pre-hardened steel

Pre-hardened steel that has been conditionally heat-treated at the factory and can be used directly for scribing.

There is no need to worry about dimensional changes and deformations caused by heat treatment, which can significantly reduce the mould manufacturing time.

Easy grinding and polishing - stable mirror finish

Mirror polishing of moulds is required to give plastic moulded products a brilliant lustre, aesthetic appearance and transparency. The smooth surface of the moulded product provides a pleasant touch and a functional aesthetic effect that is less prone to dust and dirt.

Towards the end of the mould making process, the grinding process, which is mostly carried out by hand work, requires mould steels with a stable mirror finish. The high purity of NAK80 steel makes it very easy to grind and has few problems, so it is a steel that has many repeat customers.

Excellent overlay weldability

Plastic moulds are subject to many design changes and mould modifications during the prototype phase, so overlay welding is essential. In addition, moulds that have been beautifully and finely machined can suffer from wear and tear during repeated forming operations, and sometimes require welding to repair them.

The NAK80 steel is aged to give a uniform hardness after welding, so there is no need to worry about weld marks or uneven etching, and the mirror surface can be recovered after regrinding.

Easy to etch - improving the aesthetic value of the product

It is an indispensable element in plastic products, not only for its aesthetic and premium appearance, but also for its tactile effect and for extending the life of the product.

NAK80, which has a high degree of purity and uniformity, is suitable for etching*1 and other etching processes*2, and contributes to the production of products with high aesthetic requirements.

*1: A surface treatment method that uses chemicals to etch patterns on metal

※2、Processing to give pattern patterns and embossing (processing to reverse pattern patterns on molds)

4000-115-666

Email:mojugang@gdheyi.cn

Address:No. 8, Xinwei North Lane, Fugang, Qingxi,

Dongguan City, Guangdong Province

Mobile website

Mobile website

Follow the public

Follow the public