Hello, welcome to Guangdong Heyi Hardware Products Co.,Ltd. website!

Hello, welcome to Guangdong Heyi Hardware Products Co.,Ltd. website!

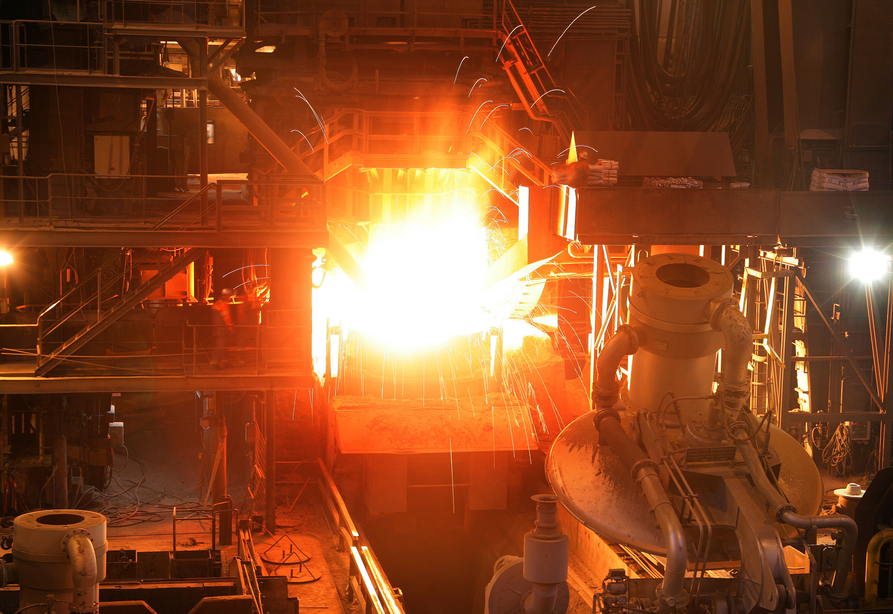

Founded in 1913, Saarland Forge has been in production for 100 years and is now part of the Saarland Steel Group. Saarland is a global leader in forging technology and melting processes, with one of the world's largest ESR and VAR facilities, and is Germany's leading forging company and today's most modern free-form forging company in the world.

Saarschmiede GmbHd has two forging plants, the old and the new, which combine traditional and modern production processes. As of 2013, the original forge has been in production for 100 years. Our new forge was opened on 8 May 2013 after almost two years of construction, with a total investment of 450 million euros. This is the largest single investment in Saarland and the largest in the entire Federal Republic of Germany. The Saarland forging plant is, so to speak, the most modern free-form forging plant in the world today.

The new forge consists of two production buildings of 550 metres in length, plus a service building, also 550 metres long. The layout of the plant is designed and constructed in accordance with the production process and is equipped with state-of-the-art equipment from smelting to finishing, as well as a pull-down forging press of 12,000 tonnes. Today around 800 skilled employees are at your service in the workshop.

Saar forging steel specialises in the production of high-quality forgings of all sizes. Saarschmiede is a global leader in forging technology and melting processes and is one of the world's top suppliers of steels for nuclear power plants, special alloys, aerospace machinery and moulds.

Saarschmiede has a complete production line from melting, forging and heat treatment through to CNC-controlled machining.

This provides the ideal basis for standard and consistent quality throughout the entire process from raw material processing to finished product formation.

Saarschmiede's complete range of equipment and process technology for the production of various steel grades is unrivalled. In addition, we are constantly investing in new equipment to ensure that we can offer our customers state-of-the-art technology. Vacuum induction melting (VIM), vacuum arc remelting (VAR) and electroslag remelting (ESR) qualities as well as triple melting qualities are the basis for advanced materials in steel mills.

4000-115-666

Email:mojugang@gdheyi.cn

Address:No. 8, Xinwei North Lane, Fugang, Qingxi,

Dongguan City, Guangdong Province

Mobile website

Mobile website

Follow the public

Follow the public